Ways to Reduce Chlorine Demand

Chlorine demand is the amount of contaminants in water that chlorine needs to destroy. Chlorine destroys contaminants either by killing (living contaminants) or oxidizing (non-living contaminants). Rather than a specific way of quantifying contaminants (in ppm), chlorine demand is a general concept used by pool operators to gauge how fast the pool consumes chlorine, and therefore how much chlorine is needed to replenish it on an ongoing basis.

Covered in this article:

- Overview of chlorination

- Types of chlorine demand

- Ways to supplement chlorine

- Enzymes

- Non-chlorine shock

- Phosphate Remover

- Secondary Systems

- Conclusion

Overview of Chlorination

Regardless of the type of chlorine you use (liquid sodium hypochlorite, calcium hypochlorite, trichlor, etc.), all chlorine will dissociate into the same two substances when added to water. Those substances are the strong, killing form of chlorine called Hypochlorous Acid (HOCl), and its slower, weaker counterpart, Hypochlorite Ion (OCl-). The dissociation is pH dependent if there is no cyanuric acid in the water, because it's all about whether or not the Hydrogen is attached or not:

HOCl ⇌ H+ + OCl-

These two forms of chlorine coexist in equilibrium, again, dependent upon pH. The lower the pH, the stronger the chlorine, because there is a higher percentage of HOCl (%HOCl is how chlorine 'strength' is defined in the pool industry). See the red line on the left chart, which represents %HOCl. The blue line represents %OCl-. Then on the right chart, the same pool has just 30 ppm of cyanuric acid, showing the %HOCl is no longer as pH dependent.

Types of chlorine demand

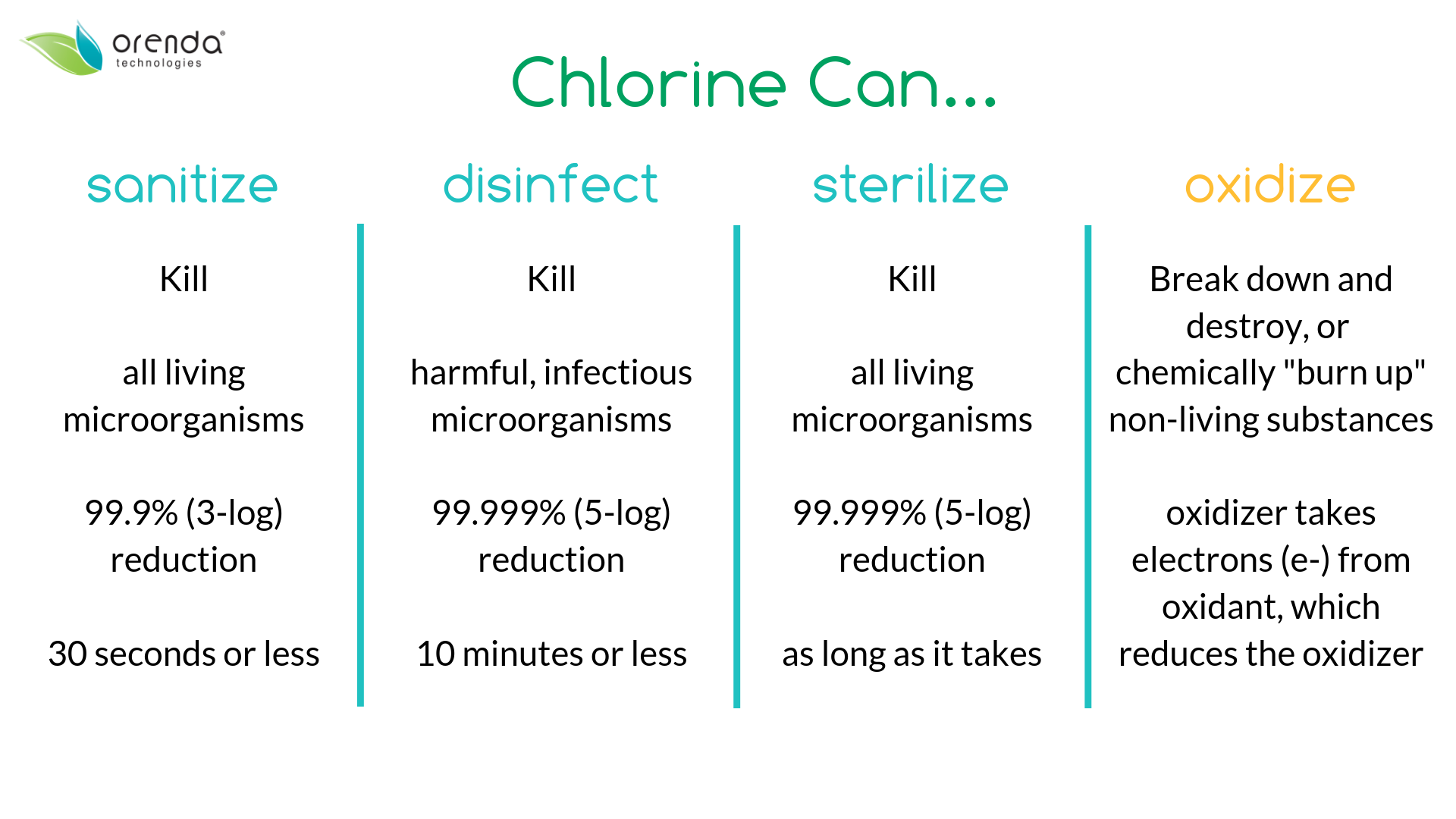

We can separate chlorine's responsibilities into two main groups: sanitization and oxidation.

Sanitization and disinfection are synonyms, because they both deal with chlorine doing it's primary job: killing. Chlorine–especially HOCl–is an outstanding residual sanitizer. It is hands down the best algaecide, the best disinfectant, and it's also safe for bathers too. These are just some of the reasons chlorine is the most popular pool sanitizer.

Oxidation is not chlorine's primary job, and it is not chlorine's specialty either. Yet it accounts for over 90% of chlorine's responsibility in swimming pools. And while oxidants make up the lion's share of the burden on chlorine, this provides us many opportunities to supplement chlorine for better water management.

There are three categories of oxidants: metals, nitrogen compounds, and non-living organics.

Metals–specifically heavy metals like iron, copper and manganese–are the easiest substances for chlorine to oxidize. They have electrons that HOCl can steal, and those electrons reduce HOCl down to inert chlorides (Cl-). Learn more about oxidation here. When enough metals are oxidized, they can oversaturate the water and begin changing the color of the water, and eventually they can cause stains. Metals generally make up a very small percentage of the oxidant demand (<3%, except in some areas, like the Great Lakes region).

Nitrogen Compounds are rarely an issue in residential pools, but are a constant issue in commercial pools. Bathers introduce nitrogen compounds through sweat and urine. Specifically, urea and ammonia. We've talked about ammonia in deck cleaners, but most of the nitrogen that gets in pools comes from swimmers that don't shower, or who pee in the pool. So, basically every swimmer.

Chlorine has to oxidize nitrogen compounds by combining with them. This creates combined chlorine. Namely, chloramines.

Nitrogen compounds take a lot of chlorine to remove. Thankfully, they still make up for a small percentage of the oxidant demand in a typical pool. BUT that small percentage takes a disproportionate amount of chlorine to address.

Non-living Organics are the vast majority of oxidants in swimming pools. So much so, that addressing them is Orenda's second pillar of proactive pool care. Non-living organics and oils are carbon-chain molecules that come from bathers, or in the case of outdoor pools, from decaying plant life too. But let's stay focused on indoor pools.

Natural body oils and waste–like sweat, dead skin, hair, mucus, and saliva–are non-living organics. And they are relatively simple to oxidize because they are natural. The more complex, chlorine-consuming organics are the body products we use. Cosmetics, lotions, deodorants, soaps, perfumes and sunscreen. These are synthetic molecules that are much more complex for chlorine to remove from water. In fact, chlorine usually falls short and cannot fully oxidize these substances, which leads to issues like tile-line scum lines.

Non-living organics typically make up over 90% of chlorine demand in general, including sanitization. So the key to addressing (and reducing) chlorine demand is to supplement chlorine against oxidants like non-living organics.

Related: Water Chemistry Resources

Ways to Supplement Chlorine to Reduce Chlorine Demand

Chlorine struggles to destroy non-living organics, oils, and bather products. Chlorine excels at killing germs and algae. So rather than throwing more chlorine at water quality problems (like combined chlorine), we strongly advise supplementing chlorine against oxidants that it cannot handle well.

INSIGHTS FROM OUR EXPERIENCE:

IN THE 360+ NATATORIUMS WE HAVE EVALUATED, we estimate that 90-95% of our clients relied solely on chlorine as a residual defense against contamination.

About 85-90% of them had a non-chlorine shock product on site, and of those, about 30% of them used non-chlorine shock weekly.

Over 80% of our clients already had a secondary disinfection system like UV, ozone or AOP. And yet, they hired us because they still had bad air quality.

Of the remaining ~20%, most of them had a UV, Ozone or AOP system, but it was not working at the time of our visit. Neglecting maintenance is a common issue amongst pool operators, unfortunately.

- Less than 10 facilities (out of 360+ that we've visited) had even tried using enzymes.

Every pool operator wants to minimize costs. And one of the largest ongoing expenses for a pool is chlorine. Naturally, this means reducing chlorine costs means reducing chlorine consumption, which means reducing chlorine demand. But how?

Supplementing with the following products can free up chlorine by reducing such non-living contaminants.

Enzymes

Enzymes are the easiest, safest, and cost-effective means of removing non-living organics from water. And for commercial pools, there's nothing close to Orenda CV-600 and CV-700. They are safe (NSF-50 Certified), yet strong enough to handle industrial wastewater treatment. Enzymes work alongside chlorine as a residual that circulates throughout the enitre pool system. They catalyze a reaction that breaks down carbon-chain organics and converts them to carbon dioxide.

Enzymes are non-living, so they are compatible with chlorine. They devour bather waste, and often make a noticable improvement to indoor air quality, as well as obvious improvements to water quality and clarity.

Non-chlorine shock

Elevating chlorine levels is not always enough to overcome the oxidant demand. Sometimes pools struggle to reach (and maintain) breakpoint chlorination. If that's the case, one option is to add a non-chlorine oxidizer shock like potassium monopersulfate (KMPS). KMPS will not disinfect the water, but it will attack all three categories of oxidants. This can be very helpful, especially after a busy swim meet.

Do not make a habit of using KMPS regularly though. If your chlorine is falling short, there are other factors at play. Perhaps consider a secondary oxidizer system like Ozone or AOP. Too much KMPS over time raises sulfate levels and that can lead to calcium sulfate scale and other issues. It's a great product, mainly because it is also a harsh product. Use sparingly.

Phosphate remover

Phosphates have become an increasingly important topic in recent years, largely thanks to water treatment facilities adding phosphates to drinking water. 20 years ago, phosphates were not so common, but nowadays they are very common. In fact, if your pool does not have a phosphate issue, that's surprising.

Phosphates are introduced via tap water, most scale and stain inhibitors (sequestering agents), and from bathers. Consider them inevitable in a commercial pool. If you use cal hypo chlorine, cal hypo tabs and briquettes contain a small amount of a phosphate-based scale inhibitor. This is not a bad thing, per se, it's just something you should be aware of.

Research shows keeping phosphates below 500 ppb is optimal for chlorine efficiency. Since phosphates themeselves cannot be oxidized and removed by chlorine, you need a phosphate remover to do the job. Fortunately there are many phosphate removers on the market. The only NSF-50 Certified phosphate remover we know if is Orenda PR-10,000.

Secondary systems

We've compared the best secondary systems in a previous article. We've also written specific articles about Ozone and UV. The most important thing to recognize about secondary systems is that most of them are point-of-contact systems, meaning they do not leave behind a residual. That means these systems do not eliminate the need for a free chlorine residual.

Conclusion

Reducing chlorine demand comes down to removing things that chlorine has to address. The less burden on chlorine, the less chlorine demand. It's pretty straightforward.

For the best bang for your buck, we recommend supplementing chlorine against the oxidant demand. Start with enzymes, which will have the biggest impact of any chemical supplement. You can also use non-chlorine shock if you're struggling to maintain breakpoint chlorination, but try not to make a habit of it. The third chemical supplement is phopshate remover, which can do wonders for chlorine efficiency.

Finally, secondary systems can have a major impact on chlorine efficiency too, though most of them are point-of-contact systems. They do not replace the need for a free chlorine residual, but they certainly help.

By

By