The Difference Between Return Air and Exhaust Air

This is a brief article to shed light on a problem of semantics in natatorium design. Too often, the terms return and exhaust are used interchangeably. They are not the same thing in indoor pools.

Covered in this article:

- What is Return Air?

- What is Exhaust Air?

- Pool dehumidification exhaust

- Chloramine recirculation vs. stratification

- Indoor pools need separate exhausts and returns

- Conclusion

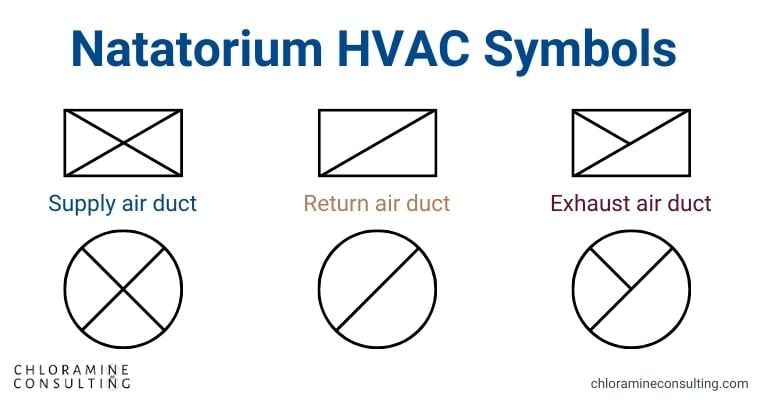

HVAC symbols are not quite universally standardized, but they are close. Some drawings will have some corners of these symbols shaded, and others will not. But generally speaking, when looking at a section of duct on mechanical drawings, you will see symbols to indicate which way the air is moving.

An (X) in the shape is supply air, a single diagonal line (/) indicates return air, and a 3/4 (X) indicates exhaust air. Returns are not the same as exhausts!

What is return air?

Return air is all the air that is drawn into the dehumidification unit from the natatorium. Its airflow is measured in cubic feet-per-minute (CFM) or its metric equivalent cubic metres-per-hour (CMH). In an ideal world, all the air in the natatorium will circulate well and regularly be returned through the Pool Dehumidification Unit (PDU) for filtration and conditioning.

In reality, however, the return intake is still pulling in a constant volume of air, but there are usually dead spots in the room.

The air volume in the room is calculated by a licensed mechanical engineer. The PDU is designed to circulate that volume of air a certain number of times per hour. The standard turnover rate is 4-6 times per hour for indoor swimming pools.

The bottom line: Return air is all the air in the natatorium that gets drawn into a duct to return to the PDU.

What is exhaust air?

Exhaust air is discarded from the facility, and blown outside. In natatoriums, this is often through dedicated exhaust fan(s), and/or an exhaust fan located within the return duct itself. Let's repeat that. Many natatoriums have their primary exhaust fan located within the return duct, or in the first chamber of the PDU. This is the reason for the confusion between the two terms.

In most commercial facilities, exhaust air is drawn from the return air duct without issue. But in indoor pools, it's a major issue. Exhaust fans do not have the capability to distinguish between airborne pollutants and regular air...so there is no mechanism to separate chloramines from fresh air.

Exhausts and returns are not the same. These should never be used interchangeably in indoor swimming pool projects. Indoor pools require a dedicated, source-capture exhaust that never crosses paths with the return airflow.

Pool Dehumidification Exhaust

One major difference that separates pool dehumidifiers from normal air conditioners is energy efficiency. PDUs are specifically designed to handle large moisture removal loads while also recovering energy (heat). This prioritization on energy recovery is known as "closing the energy loop". Otherwise, facilities would just be exhausting warm, conditioned air to the outside, and lose all of its energy. It cost money to condition that air in the first place.

Modern-day PDUs can take reclaimed heat and transfer it to the pool water, or simply pre-heat the new outdoor air coming into the system.

For optimal energy efficiency, good mechanical engineers use the ASHRAE 62.1 minimum outside air standard. Unfortunately, while the ASHRAE standard is solid, there are many interpretations of it that can lead to issues. So to combat this and reduce risk of bad air quality, engineers have to walk a fine line between energy efficiency and indoor air quality. This can be a real dilemma, especially for an engineering firm who has never designed for an indoor swimming pool.

What we see most often is PDUs are increased in size and capacity to handle more outside air than ASHRAE requires. Sounds great, right? But...it comes at a cost too, and it does not necessarily solve the issue of indoor air quality. In our experience, it almost never does.

Related: Five Common Mistakes in Natatorium Design

So for decades, PDUs became increasingly efficient at reclaiming heat, and to do so, they made the exhaust air part of normal circulation pathway, after its heat was recovered. In other words, the actual discarding of air occurs within the PDU itself, and is drawn from the return air stream. From an energy standpoint, it makes sense. From an air quality standpoint, however, it can quickly become problematic.

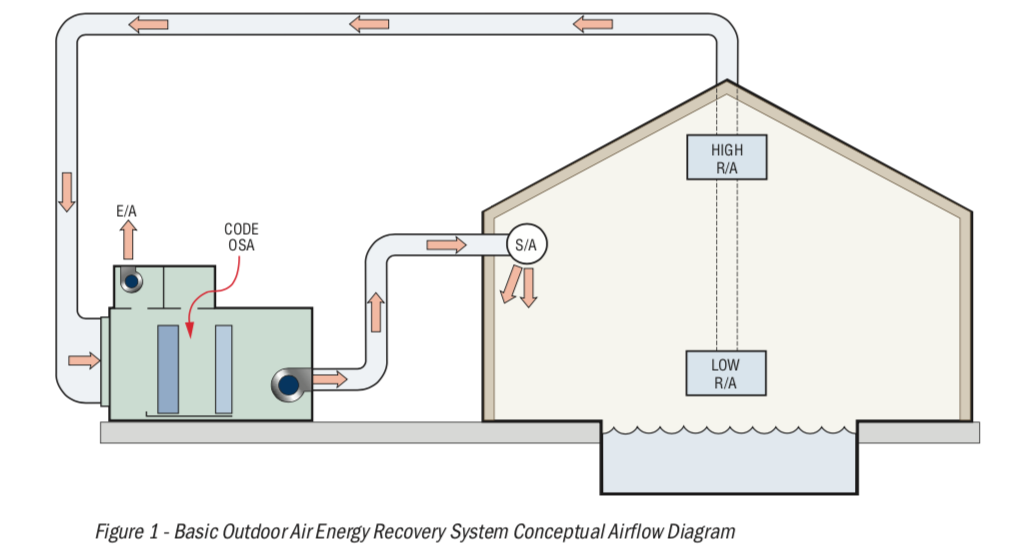

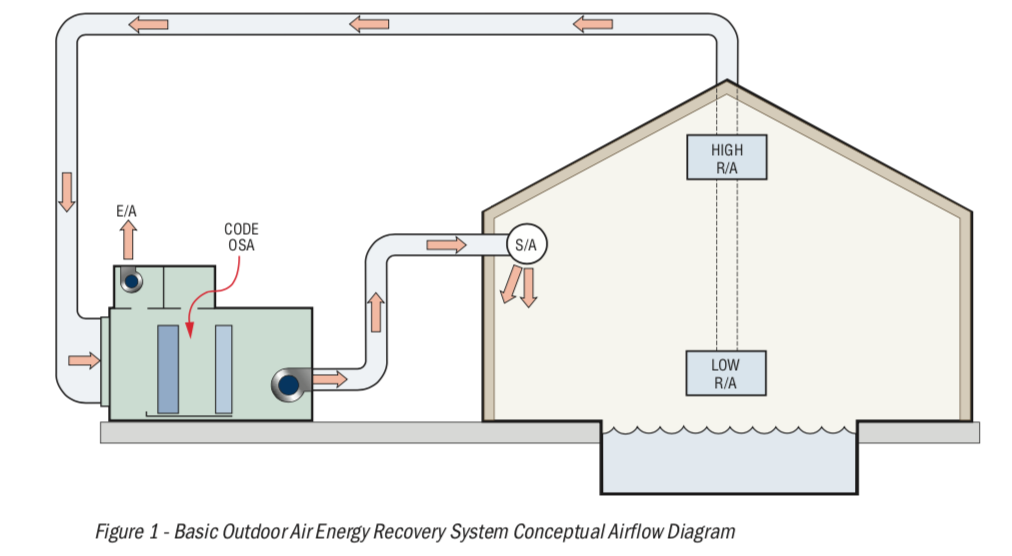

Diagram is from Desert Aire Corp., used with Permission

The diagram above shows return air being pulled through the PDU, then exhausted (E/A) from the PDU itself. While this diagram does not show specifics, many PDUs like this sometimes run the return air through a set of coils to reclaim heat prior to the air being exhausted. But that's not the point we're trying to make.

The point is, on mechanical drawings and blueprints, the return air duct will just be labeled return. Even though that same duct is being used for the natatorium exhaust.

Here's why semantics matter so much: if we confuse return air with exhaust air, natatoriums will continue to be designed improperly. We may have low returns when we really want low exhausts, or vice versa. We see this all the time, and it's a costly design mistake.

Chloramine recirculation vs. stratification

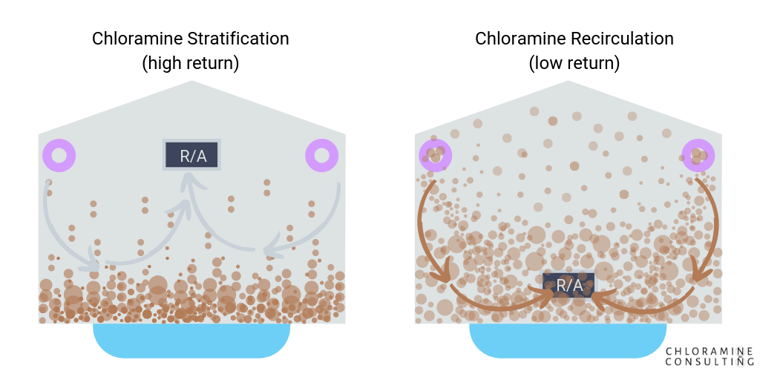

Natatorium IAQ problems tend to fall into one of the following categories: a stratification problem or a recirculation problem. Stratification is when trichloramines and trihalomethanes and other DBPs, which are heavier than oxygen, build up in the bottom of the room, starting in the swimmers breathing zone. With poor circulation and air movement, this chloramine bubble builds and builds. Natatoriums with a stratification problem have a perpetual pool smell, a constant irritation and if bad enough, rust and corrosion in the natatorium. These rooms usually have high returns, and the chloramine bubble must build high enough to be diluted out. It's a mess.

The opposite problem, chloramine recirculation, may actually be worse. Low returns pull the chloramine bubble into circulation, and stir everything up. This may be more pleasant during light use, but when the swim team gets in, the air quality can go from decent to horrible within one air exchange (10-15 minutes usually). This issue continues to compound itself. When the production rate of DBPs exceeds the dilution rate of the air handling system, air quality issues compound themselves.

Pools with a chloramine recirculation problem tend to have rust and corrosion everywhere, not just low in the room. We're talking the ceiling, inside the PDU, computer equipment, scoreboards and other electronics, and everything in between.

Both of these issues can be prevented.

Indoor pools need separate returns and exhausts

Ask yourself: can an exhaust fan can identify which air is good, and which is bad? Can it separate chloramines from fresh air?

Of course not. But source-capture exhaust can separate the bad air from the good, and keep the bad from circulating through the main PDU, corroding everything in its path.

After-market retrofit Paddock Evacuator® bench system. On new pools, however, the Evacuator should be installed as part of the perimeter gutter or in the deck drain. Nobody will ever know it's there, and it is grabbing chloramines as close to the source as possible.

Believe it or not, the freshest air in a natatorium is usually at the top of the room, up by the ceiling. Sure, it's warm and humid air, but chloramines are heavier than oxygen and stay low in the room. If we truly want to optimize pool dehumidification and indoor air quality, we must separate the exhaust from the return.

Conclusion

Consider both high and medium return duct heights to reclaim the warmest, most humid air to pull through the PDU. In a completely separate airstream, exhaust low with source-capture technology. If you want to go a step further, there is an energy recovery option designed specifically for a source-capture exhaust, and it is completely separate from the main PDU and its fresh air circulation.

Here at Chloramine Consulting, our first priority is the health and comfort of an indoor swimming pool. We care first and foremost about air quality. Energy efficiency is a secondary priority, though still important. The good news is, the amount of dedicated source-capture exhaust needed for great indoor air quality is a small percentage of the total return air volume.

So when you're looking on mechanical drawings and you see ducts labeled "return" or "exhaust", look carefully and add up the CFM of each fan and system. The designer might be confusing the term, or using it to represent both. It's an issue with semantics, but they are semantics that can be very costly to a natatorium in the long run.

By

By