Two Types of Airflow Problems in Indoor Pools

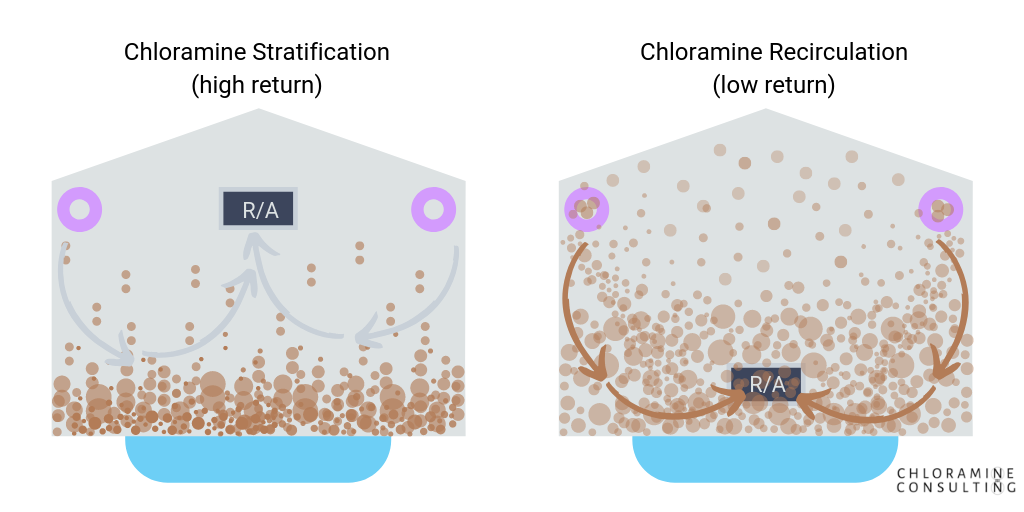

In natatoriums, indoor air quality problems typically fall into two categories: Recirculation (where chloramine pollution is pulled into the dehumidifier's return intake and blown back into the room, corroding everything in the system), and Stratification (where chloramine pollution stays low in the room and builds in density, because the HVAC's return intakes are too high to pull them out). Both cause corrosion and can lead to swimmers coughing and being generally uncomfortable.

Covered in this article:

- Supply and return airflow designs

- Two types of airflow problems in natatoriums

- How to improve indoor air quality

- Conclusion

Supply and Return airflow designs

First, let's take a step back and look at the natatorium as a whole. It's a building with a swimming pool in the floor. The swimming pool introduces factors that do not exist in most commercial spaces (like gymnasiums, auditoriums, cafeterias, classrooms, etc.). These factors–like moisture loads, relative humidity, vapor pressure, higher temperatures and chloramine pollution–make indoor pools notoriously difficult to design.

One of the most common mistakes engineers often make is simply following ASHRAE §62.1 without context for how the pool is used and the pollutants that off-gas from it. We are grateful that engineers follow the book and design to the standard...but we hope to guide them in how to apply what §62.1 is saying into reality. In other words, we don't want engineers to face the dilemma of potentially designing a flawed natatorium that is destined to cause indoor air quality problems for swimmers and everyone else inside.

Most of our clients have had a properly-sized HVAC system. Most of them have had adequate duct sizes, airflow volumes, and turnover rates too. In fact, most pools have been designed to ASHRAE §62.1 through and through.

And yet the air quality can still be awful, making swimmers cough.

Supply air

The air pattern and volumes of conditioned air flowing into the natatorium is determined by the supply duct design. Engineers should have no issue calculating air volumes and conditioning specifications, especially with the help of a pool dehumidifier manufacturer. These companies specialize in conditioning indoor pools. They will give specific design parameters to the mechanical engineer, and even provide some guidance on duct layout...but ultimately it's up to the mechanical engineer to design the duct that can handle the specified air volume.

This is where things go wrong.

Sure, you've got the right amount of airflow. You probably have the right sized duct to handle that airflow too. But is the air being delivered in the right places, at the right velocity? Usually not

Where matters more than how much

When it comes to natatorium supply air, in our opinion, the direction(s) of airflow is the most important thing. Even some under-designed PDUs can perform well when the airflow is moving where it should be. Of course, we want properly sized equipment and ducts too, but you could have the best dehumidification system in the world (even over-sized for good measure) with a poor supply airflow design and the air quality will suffer. So whereyou move the air matters more than how much air you're moving.1

Return air

The return intake is usually a set of grilles on a wall, or a rigid duct with intake vents. This is where all of the air in the natatorium is drawn to and pulled into the dehumidifier. The location of the return–specifically the height of it–plays a major role in the airflow of the room. The return location is the primary factor between the two main types of airflow problems in natatoriums.

Two types of airflow problems in natatoriums

In the diagram above, we show a high return (left) and a low return (right). As you can see, a high return leads to a stratification problem; chloramines stay low in the room–because they are heavier than oxygen–and have no place to go. Conversely, a low return leads to a recirculation problem, because chloramines are drawn into the dehumidifier and recirculated back into the room.

Related: Swimming Pool Air Quality Resources

Stratification

Natatoriums with a stratification issue tend to have unfavorable air quality 24/7. It's never good, and it gets worse when the pool is busy. Rust and corrosion of metal components are found all over the place, especially near the floor. The lower in the room, the more rust will be found. This is why lifeguard stands and backstroke flag poles tend to be very rusty at the bottom and less rusty at the top.

Chloramine pollution will continue to build and build–displacing oxygen–and the air feels stagnant and sticky. Humidity is also a major issue in these facilities. The pool smell lingers and often sticks to your clothing and skin after you leave the pool.

All that being said, those who regularly swim or work in these natatoriums tend to get used to it and it is difficult to know the difference in air quality from day to day. It's always bad.

Recirculation

While natatoriums with high returns and stratification problems can be miserable 24/7, that is not the case for pools with low returns and recirculation issues. Because the return intakes are low to the ground, chloramine pollution tends to move and get drawn into the return with the rest of the airflow. A portion of this is exhausted (usually about 15%), and then outside air is brought into the dehumidifier. This helps dilute the chloramines.

The issue here is that those same chloramines that are drawn into the system will be blown through the system, corroding everything in their path before flowing right back into the natatorium through the supply ducts. Recirculating chloramines through a dehumidifier is akin to chain smoking cigarettes.

During low-use times at the pool, air quality can be pretty decent. But as soon as the bather load picks up (like a swim practice or meet), conditions decline rapidly. The problem compounds itself quickly when the chloramine off-gas rate exceeds the dilution rate of the dehumidifier.

So while high-return natatoriums have general discomfort all the time, low-return natatoriums have periods of extreme discomfort, contrasted by periods of relatively pleasant conditions.

How to improve indoor air quality

While chloramines and other disinfection byproducts (DBPs) can be mitigated by water chemistry and secondary systems, they cannot be prevented completely. Once these pollutants off-gas into the air, they become an air problem.

In our experience, the best way to improve the indoor air quality is to target and capture the pollution and exhaust it from the room. This requires properly-designed source-capture exhaust and an adequate supply airflow design. Sometimes modifications to the supply and return ducts are necessary for this to work.

An optimal design is possible which would prevent both chloramine recirculation and build-up, while allowing air to circulate well. Here's an example from Desert Aire's website:

Many facilities have tried to build their own source-capture exhaust system, but it is not as simple as it sounds. A clear understanding of chloramine behavior and air physics is necessary for success. In other words, you need to know what you're looking for when you examine a natatorium to see what needs to be modified. And that's the service we provide to mechanical engineers and facility owners. Our facility evaluation service gives a detailed report with specific guidance to a design team to remedy the issue at a fundamental level.

Conclusion

The ideal facility layout will have neither a stratification nor recirculation problem. We want air to circulate correctly, we just don't want chloramine pollution to recirculate. With design assistance, you can have the best of both worlds and provide fresh air to swimmers, coaches and lifeguards. Removing chloramines from the recirculation path also reduces corrosion on evaporator coils and other expensive internal parts of the dehumidifier.

1 Without a doubt, moisture removal rates and airflow volumes are important. We're just saying they are easy to calculate. The more difficult task that is often overlooked or mishandled is the directional airflow of the supply air. To us, that's where most indoor air quality improvements can be made. It's rare to find a natatorium that does not have a dehumidifier that meets design minimums set by ASHRAE §62.1 for air volumes and moisture removal...and yet the majority of those same facilities have poor airflow design and bad indoor air quality as a result.

By

By