Safe Pool Chemical Storage

Swimming pools need chemicals to stay clean and balanced, but make no mistake, these chemicals can be dangerous. This article covers common pool chemicals and how to store them safely, as well as hazardous mistakes to avoid.

This article is mostly aimed at pool owners and operators, but if you are a design professional reading this, please consider these things when you are designing a natatorium. Separate storage rooms with plastic door handles and hinges, good ventilation, and overall storage space are critical for operator success and safety.

How to safely store chlorine and other pool chemicals

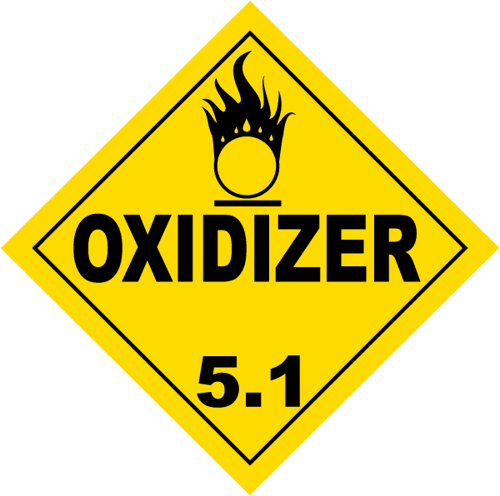

Chlorine is a swimming pool's primary sanitizer and disinfectant, as well as its primary oxidizer. You may recognize the oxidizer symbol as a circle on fire. It's a warning label telling us something: this chemical is volatile!

Chlorine is a swimming pool's primary sanitizer and disinfectant, as well as its primary oxidizer. You may recognize the oxidizer symbol as a circle on fire. It's a warning label telling us something: this chemical is volatile!

Chlorine needs to be stored separately from:

- any other types of chlorine

- any type of acid

- metal equipment and electronics

Different chlorine types must be separated

Mixing two types of chlorine together is often a fire/explosion hazard. Never mix or even store them near each other. As a rule of thumb, if they are two types of chlorine, they should not be in the same storage room, period. The vapors alone can cause a fire or explosion. In most commercial pools, primary chlorine is stored in a specific room, and if there is a secondary shock, like granular cal hypo, it is kept in either a different room, or at least 10 feet (~3 m) away. Good ventilation is key.

If chlorine and acid are mixed together, the fumes are toxic and potentially lethal. Acids, however, when sealed properly, can be stored in the same room as chlorine, provided there is sufficient ventilation and space between the chemicals. Commercial pools tend to use automated feeders for liquid acid and liquid chlorine, but we strongly recommend having these two chemicals in different rooms.

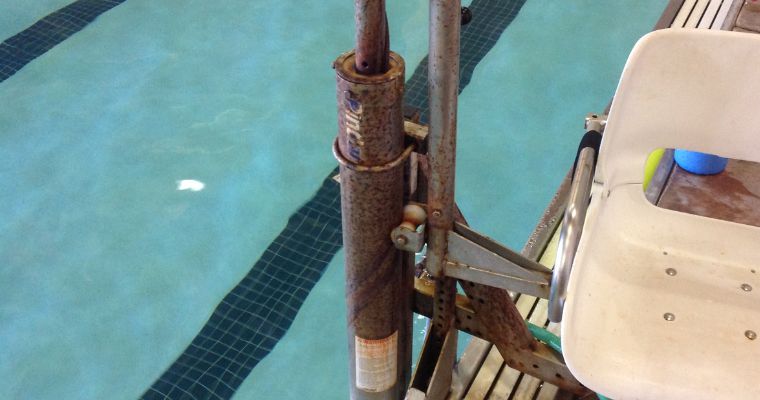

It is astounding how many commercial pump rooms are corroded beyond repair. This corrosion is the result of bad/insufficient ventilation and/or bad chemical storage practices. Both acid and chlorine have fumes that will destroy steel. If airborne chloramines can corrode 316L stainless steel in the natatorium, you don't have to imagine what pure acid and chlorine fumes will do to a pump room. We'll show you. Here are some photos:

These photos are just a taste of what can happen. Tens of thousands of dollars worth of equipment get rusted out because of bad ventilation and chemical storage practices. Keep that in mind if you're a pool owner or operator. It's probably worth looking at your storage practices and ventilation simply as an insurance policy against expensive damages. We have seen destroyed pumps, controllers, filters, valves, bolts, structural steel, and just about everything else metal.

Dry chemicals above liquids

Never store liquids above dry chemicals. If you're using liquid acid, chlorine, or anything else, there's always a risk of leaks, and gravity is unforgiving. Dry chemicals, on the other hand, rarely leak (unless a bag rips open, then you have to ask yourself why you would put a paper bag of chemicals high up on a shelf). For that reason, liquids are always stored low in the room, and dry chemicals would be stored higher if space is limited.

Never store liquids above dry chemicals. If you're using liquid acid, chlorine, or anything else, there's always a risk of leaks, and gravity is unforgiving. Dry chemicals, on the other hand, rarely leak (unless a bag rips open, then you have to ask yourself why you would put a paper bag of chemicals high up on a shelf). For that reason, liquids are always stored low in the room, and dry chemicals would be stored higher if space is limited.

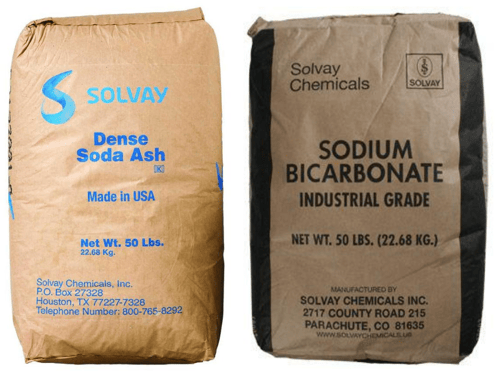

An even better practice is to transfer dry products–like sodium bicarbonate, soda ash, sodium thiosulfate, etc.–into clean buckets with a lid. Clearly label the bucket, of course. Plastic buckets are far more durable than paper bags of products.

Wet floors and spill containment

Let's face it: pools, pump rooms and chemical storage rooms often have wet floors. Use common sense and don't store cardboard or paper bags (like sodium bicarb or soda ash) on the ground. Plastic buckets, chemical drums and containers are fine on wet ground, but not containers that will deteriorate and get soggy. We have seen enough soaked bags of bicarb to know they are not fun to clean up. The best practice here is to store bags of bicarb on a pallet, or some other raised platform to keep the bags dry.

As an aside here, maintain the floor drains. We have been in many pump rooms that the drains are either clogged up or obstructed by debris. Keep them cleared and open so water can effectively drain.

Spill containment is very important as well. With liquids especially, chemicals can wreak havoc in a storage room or pump room. It's not so much "if" a liquid spills, it's more of a "when" it spills. Spills are virtually guaranteed to occur once in a while, so containment bins are a must-have.

They come in many shapes and sizes, but basically, a containment bin is a plastic tray that can hold a certain amount of liquid and keep it from spreading out onto the floor. The concept is simple, affordable, and worth every penny. These trays also keep chemical containers off the ground, which reduces the risk that something like chlorine could leak on the floor and interact with some spilled acid. It keeps the chemicals in one place–and perhaps more importantly, separated. The photo above shows a pool service company's setup for storing and using 55-gallon drums of enzymes and phosphate remover. Similar containers are available for various types of chemicals you may use in your pool, whether you want horizontal drums or vertical.

They come in many shapes and sizes, but basically, a containment bin is a plastic tray that can hold a certain amount of liquid and keep it from spreading out onto the floor. The concept is simple, affordable, and worth every penny. These trays also keep chemical containers off the ground, which reduces the risk that something like chlorine could leak on the floor and interact with some spilled acid. It keeps the chemicals in one place–and perhaps more importantly, separated. The photo above shows a pool service company's setup for storing and using 55-gallon drums of enzymes and phosphate remover. Similar containers are available for various types of chemicals you may use in your pool, whether you want horizontal drums or vertical.

Lock the doors

It should go without saying, but pump rooms and chemical storage rooms should be locked up. Only certified operators should have access to pool chemicals and equipment. Who knows what kids could do in there? When in doubt, assume all pool chemicals are dangerous, even if not all of them are. And within a locked chemical storage room or pump room, access to certain things should be controlled too. For instance, not everyone needs to be able to open the face of a chemical controller, or fiddle with electrical wiring.

It should go without saying, but pump rooms and chemical storage rooms should be locked up. Only certified operators should have access to pool chemicals and equipment. Who knows what kids could do in there? When in doubt, assume all pool chemicals are dangerous, even if not all of them are. And within a locked chemical storage room or pump room, access to certain things should be controlled too. For instance, not everyone needs to be able to open the face of a chemical controller, or fiddle with electrical wiring.

To be fair, most commercial pools will not meet health code if the pump room and chemical storage rooms do not have locks. But believe it or not, we have seen pools without them! Check out the photo here where the staff cleverly used a 3/4" PVC pipe to keep the doors "locked". It's kind of funny, but more alarming than anything.

Safety items

Beyond storing chemicals, safety equipment is also very important. There are the emergency items, such as AEDs, fire extinguishers, emergency phones, eyewash stations, first aid kits, and neck-injury backboards. There are also emergency protocols, which are usually written and laminated in an easy-to-read location. Then there are material Safety Data Sheets (SDS, or MSDS), which are detailed reports on every chemical used in the pool. SDS sheets, by most health departments, must be stored in an easy-to-find location in case of an emergency or health inspection.

Beyond storing chemicals, safety equipment is also very important. There are the emergency items, such as AEDs, fire extinguishers, emergency phones, eyewash stations, first aid kits, and neck-injury backboards. There are also emergency protocols, which are usually written and laminated in an easy-to-read location. Then there are material Safety Data Sheets (SDS, or MSDS), which are detailed reports on every chemical used in the pool. SDS sheets, by most health departments, must be stored in an easy-to-find location in case of an emergency or health inspection.

Conclusion

Safe pool chemical storage involves quite a few things. In no particular order:

- Keep pool chemicals safely stored to avoid leaks and spills

- Never store liquids above solids (to prevent potential hazards if leaks occur)

- Use spill-containers, because leaks are virtually inevitable at some point

- Keep chlorines and acids separate from each other

- Good ventilation is essential to help prevent rust/corrosion and vapor interactions between chemicals (which can be very dangerous in itself!)

- Lock doors and restrict access to chemicals and equipment so only trained staff can get to them

- Keep safety procedures and SDS sheets easily accessible at all times.

If you follow these safety measures, risk is reduced, and everybody wins. Cutting corners leads to problems and costly equipment deterioration.

By

By